Breadcrumb

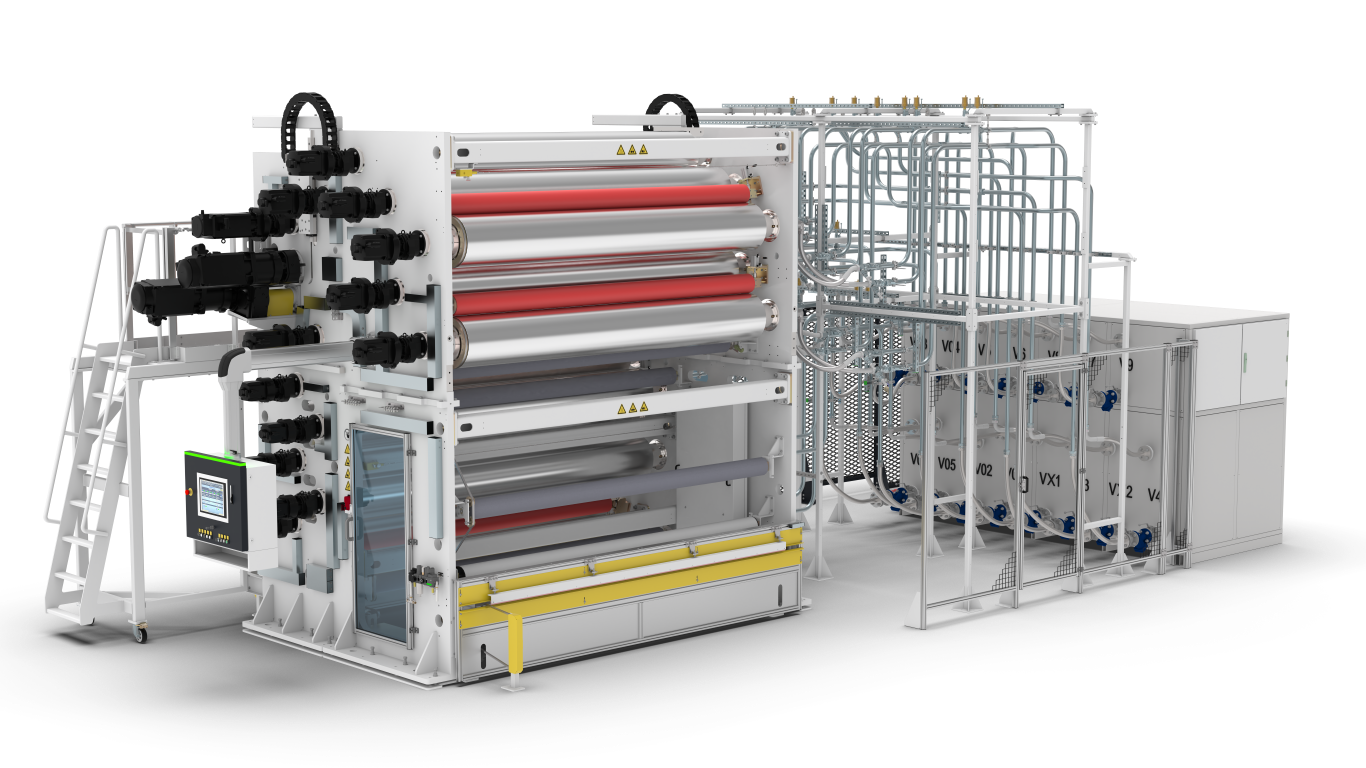

Cast MDO technology: The superior technology for mono-material packaging solutions

Cast MDO technology marks a significant development in mono-oriented PE film production. By combining precise thickness control across a broad thickness range, outstanding optical properties, and customisable barrier options, it provides packaging manufacturers with a versatile and sustainable solution that meets the highest standards of quality, efficiency, and performance.

New development: MDOPE cast film for deep-freeze applications without the need of lamination

SML’s latest generation of cast MDO lines have successfully produced a new, unlaminated MDO-PE film optimised for deep-freeze packaging. This film enables downgauging by up to 50% compared to conventional deep-freeze structures, while maintaining mechanical strength and excellent sealing properties. The cast MDO process ensures exceptional processability across a wide thickness range from 15 µm to 65 µm. These MDO-PE films are produced at line speeds of up to 380 m/min and then successfully printed at speeds of up to 500 m/min. Optimised resins and film layer structures deliver stiffness, puncture resistance, and sealing performance without the process of lamination. “This joint development with TotalEnergies underlines SML’s ongoing commitment to innovation in cast MDO technology and sustainable flexible packaging solutions,” explains Elias Mayrhofer, Product Manager, Cast Film Extrusion at SML.

Precision and appearance at the highest level

Cast MDO technology delivers films with significantly enhanced optical properties, including exceptional gloss and clarity, combined with outstanding flatness and a perfectly uniform thickness profile. This is achieved through precise die regulation with thickness measurement after the MDO unit, compensating neck-in and ensuring best winding quality. Excellent cooling rates on the chill roll enhance surface smoothness and mechanical properties, while integrated edge-trim recycling supports sustainable production in a closed loop system. “These unique performance features are unmatched by any other technology currently available on the market. The result is a premium mono-oriented film, ideal for demanding applications where visual quality and dimensional consistency are most important,” Mayrhofer further states.

Barrier layers for extended functionality

For sensitive products requiring high barrier properties, a barrier layer of EVOH or PVOH can be integrated into all MDO-PE film structures. Cast MDO-PE barrier films are available in thicknesses from 17 µm up to 65 µm. Compared to unstretched barrier structures, the orientation (stretching) process enhances the barrier performance at the same EVOH content within the film. This ensures superior protection while maintaining recyclability due to the low proportion of the barrier material in the film structure.

Redlham, 04.09.2025