Breadcrumb

SML launches new twin-screw extruder at K 2025

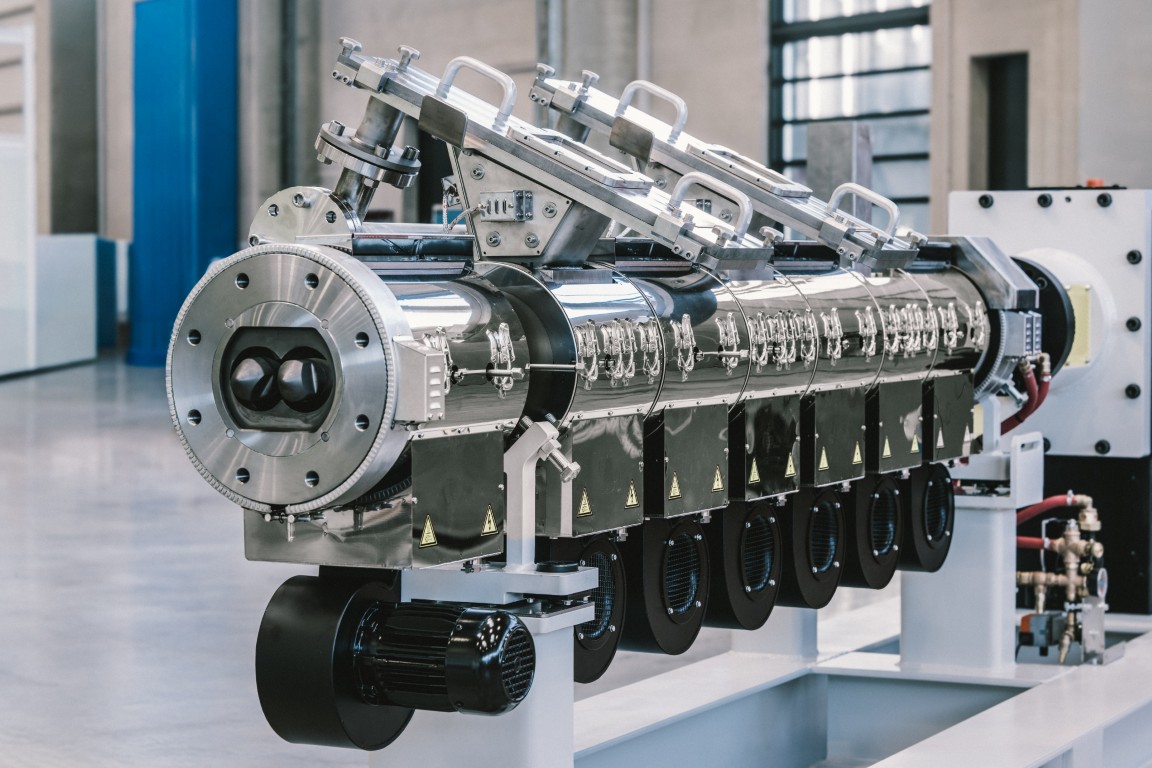

SML is expanding its extruder portfolio with the introduction of a co-rotating twin-screw extruder (TSE). This addition marks a significant enhancement of SML’s offerings, allowing the company to provide a more comprehensive range of extrusion solutions to its customers.

The brand-new TSE is SML’s answer to the increasing demand for high-output capacities for polyolefins and polyesters. “Our in-house-designed co-rotating twin-screw extruder is tailor-made for the specific requirements of our extrusion lines, contributing to an exceptional film quality,” states Hans-Jürgen Luger, Head of Research and Development at SML.

Compact size benefits energy consumption

Compared to a large single-screw extruder with the same output capacity, the TSE has a shorter processing unit and, thus, a smaller footprint. Therefore, less heating power is required to maintain the barrel temperatures. Because of starve feeding, the extruder drive operates at high torque over the entire output range, where it exhibits the maximum efficiency. Additionally, the melt temperature can be controlled by adjusting the degree of filling. Extensive tests of the new TSE on a CPP line in SML’s Technology Centre have shown that the specific energy input (SEI) is 10-15% lower compared to a single-screw extruder. In terms of film quality, the gel count detected by a web inspection system could be reduced by up to 20% for a standard CPP film.

Optimised for high-performance cast film lines

One area of application with considerable potential is SML’s cast film lines. “With throughputs in the range of 1,000 to 2,000 kg/h, the TSE is ideal for our high-performance cast film lines with end film widths of up to 6.5 metres,” explains Elias Mayrhofer, Product Manager at SML.

Clever design and low maintenance

The swivel-mounted barrel design allows rear screw extraction for quick and easy screw changes. The temperature control of the barrel works via ceramic heaters and air cooling – which is a precise, cost-efficient, and low-maintenance solution. SML offers pre-configured single-piece barrel designs of different lengths and with venting ports depending on the application. For the extruder screws, single-piece solutions or shafts with segments are available.

PET without pre-drying and in-line compounding

In combination with SML’s high-performance vacuum unit, SML can offer a complete in-house extrusion solution for processing PET or PLA without pre-drying. Furthermore, the TSE enables high amounts of regrind or flakes to be processed as well as in-line compounding.

For demonstration and further development, a test extruder is available in the SML Technology Centre.

Redlham, 04.09.2025